Technical Newsletter

Issue 10

Project Information

Name: Woodland Heights

Product:AB Classic

with No-Fines Concrete

Size: 1400 ft² (130 m²) long, 8 ft (2.4 m) tall

Allan Block Manufacturer: Amcon Block

No-Fines Installation

Permeable Concrete

Superior Wall Drainage

Use with any Allan Block Retaining Wall

Fill Voids in Blocks and Backfill

Allan Block Retaining Walls and No-Fines Concrete - No Problem

Woodland Heights, a 30-unit townhome association built in the 1980’s, needed to replace its second timber retaining wall. However, numerous site constraints did not allow enough clearance to install geogrid reinforcement within the property limits. Based on site constraints and project goals, Duffy Engineering and Associates called for the use of No-Fines concrete backfill with an Allan Block AB Classic retaining wall. Duffy utilized AB Walls 10 software’s alternative reinforcement option to design the wall and confirm that all safety factors were exceeded.

No-Fines concrete has been utilized in the construction industry for decades and the segmental retaining wall industry for more than 15 years. Like most concrete mixes, No-Fines concrete includes portland cement and coarse aggregate. However, sand (fine aggregate) is omitted from the No-Fines mix to allow voids to develop, thereby creating a permeable, yet very strong material.

After receiving approval from the City, The Lawn Ranger Inc. proceeded with construction in a series of phases to minimize potential water management and slope stability issues during construction. This turned out to be a good decision because, midway through construction, the site received 4 in. (100 mm) of rain over 48 hours. Fortunately, the contractor planned ahead and covered the entire work area with large tarps.

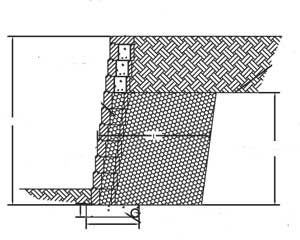

The wall was built by placing No-Fines concrete in the block cores and 2.5 ft (0.76 m) behind the block retaining wall in two course increments. Once the placement of the No-Fines backfill was completed, the crew began stacking the next two courses of block. By the time the blocks were in place, the first lift of concrete had cured enough to place the next lift. This process was repeated until the top of the wall was reached. In the end, 40 cubic yards (30.6 cubic meters) were placed within the retaining wall structure.

Since the footprint of the No-Fines concrete retaining wall was smaller than that of a geogrid reinforced wall, the expense of hauling the excavated soil offsite was minimized. This successful project outlines how No-Fines concrete can provide a cost effective way to build a segmental retaining wall when space behind the wall is limited. For more information on this story, check out the Woodland Heights case study.

No-Fines Concrete History:

Wimpey House

No-Fines concrete construction had its first boom in England after World War II where it was used in the construction of homes known as the Wimpey Houses. Since labor was in short supply and skilled masons were hard to come by, George Wimpey developed a system where unskilled workers could form up and pour No-Fines concrete walls for the multi-story homes.

No-Fines concrete was used because it exerted less pressure on the forms while being more mobile than traditional concrete mixes. The term ‘No-Fines concrete’ became ‘pervious concrete’ once the most popular use became pavement applications.

No-Fines Concrete Backfill

Use of AB No-Fines concrete backfill has increased our ability to install reinforced retaining walls in locations where typical construction would not be possible because of property line constraints or limited excavation options. When using the Allan Block products with No-Fines Concrete, the permeable concrete actually attaches to the back of the block and extends the depth of the retaining wall mass. This allows for taller retaining walls with less excavation than conventional geogrid reinforced retaining walls.

Typical geogrid reinforced retaining walls require an excavation depth of 60 percent or more of the retaining wall height; while a No-Fines reinforced retaining wall, with similar site conditions, requires only 30 to 40 percent of the retaining wall height. Limiting the excavation depth will not only save time and money, but it might make the difference between getting the job or not.

There are additional advantages to using the No-Fines solution. Contractors are able to build with better production rates and with less manpower. The use of No-Fines Concrete backfill also eliminates the need for compaction and compaction testing of the reinforced soil. It provides superior wall drainage since the entire mass is permeable; therefore eliminating the need for drainage rock in the cores and behind the retaining wall. This pervious concrete backfill will provide a “solid” solution that can reduce the overall settlement behind the retaining wall

Engineering Properties:

- No-Fines Concrete Backfill can be used with any of the Allan Block Retaining Wall Collections.

- No-Fines Concrete Backfill typically consists of cement, fly ash, water and coarse aggregate. The quantity of cementitious material is approximately 500 lb/yd³ (297 kg/m³)with a water/cement ratio of approximately 0.30 – 0.40.

- No-Fines Concrete Backfill is design using 3/8 in.to 3/4 in. (9.5 mm to 19 mm) aggregate with an aggregate/cement ratio of 6:1.

- The density of this product will vary with the density of the aggregate used, but will typically range between 100 lb/ft³ – 135 lb/ft³ (1600 kg/m³ – 2160 kg/m³).

- No-Fines Concrete Backfill has little to no slump and exerts pressure on the soil and Allan Block wall similar to loosely poured aggregate until cured.

- When using No-Fines Concrete Backfill, the backfill zone will also serve as the required drainage or wall rock zone within the cores and directly behind the wall.

Installation Steps:

Refer to the AB Commercial Installation Manual for the complete installation steps when preparing the base trench and installing the first course of blocks. Once the first course of blocks are installed and leveled, following these simple steps to place the No-Fines Concrete Backfill:

Placing No-Fines Concrete Backfill – Fill all the voids in the block and backfill to the specified depth with the No-Fines Concrete. Obviously, there are numerous ways to get the concrete mix to the back of the wall. Each site will be different.

- It is recommended, but not required; for straight retaining wall sections, one of the back wings of the Allan Blocks be removed to help secure the block face to the concrete backfill.

- The vertical height of a pour should not exceed 16 inches (406 mm) or two courses of block.

- Additional pours can be made as soon as the No-Fines concrete backfill in the previous lift has set, which is usually not longer than 2 to 3 hours. Additional courses of block could be stacked while waiting for the backfill to cure.

Additional Courses – Brush the top of the blocks to remove any excess material. It is recommended that this be done before allowing the concrete to harden. Install the next course of blocks ensuring that they are level. Place the No-Fines Concrete Backfill the same way as outlined in the previous step. Continue these steps until the wall reaches its designed height.