Technical Newsletter

Issue 32

Bridging Between Problems and Solutions

Geosynthetic Reinforced Soil – Integrated Bridge System (GRS-IBS) is being used to help solve the growing national demand to replace small, single-span bridges. The Federal Highway Administration (FHWA) has been pushing this design and construction method for over 10 years. GRS-IBS bridges provide a low-cost and durable solution that also requires less construction time. This was the advantages Hamilton County and the Indiana Highway Department were looking for - considering they had four bridge structures that needed to be replaced. Since the county was funding the project, they were looking for the best way to remove and reinstall. Their first bridge project was an 11 ft high by 24 ft wide (3.4 x 7.3 m) wood piled bridge structure that needed replacing.

When designs were considered for the bridge the county was definitely looking at both the budget and the time required for construction. Therefore, conventional designs and standard driven pile systems were not the best alternatives. By utilizing a GRS-IBS application they were able to construct the new bridge in a matter of weeks instead of months. Additionally, they estimated that the GRS-IBS application would save Hamilton County over $500,000.

The use of Allan Block as the block facing provided the best solution when compared directly to the concrete masonry units (CMU) that are traditionally used for construction. In fact, the local Allan Block sales representative, Jill Fouts with Reading Rock, actually stacked up Allan Block and CMU units side by side for the design team to consider. The quality of a segmental retaining wall unit regarding durability and height tolerance far exceeds the traditional CMU units. To incorporate the Allan Block into the GRS-IBS structure, Civil Design Professionals looked at the wall designs and provided the drawings for Hoosier Pride Excavating. Because of space limitations they decided to utilize the AB Vertical to minimize the setback of the abutment structures. StrataGRS 4800 Geotextile, from StrataGrid Inc., was chosen as the reinforcing material since it is specifically designed for the GRS-IBS applications.

What was interesting about this project was how the actual bridge superstructure was constructed. Very often the bridge structure will incorporate precast concrete or even steel beams to span the distance between the GRS-IBS abutments. However, for this project they utilized the existing wood piles from the old bridge to support the steel form work. The concrete deck was poured just beyond the bridge seat and once it was cured the steel supports and beams were removed. The piles were then cut off at grade and ultimately covered by rip rap.

Installation time was minimal which meant that replacement of the bridge was completed within budget and the strict time constraints of the project. In fact, here are some of the things Hamilton County learned from the four bridge projects:

- The first two abutments used corners which they estimated added a full day to incorporate. The second two bridge projects rounded the abutment corners which saved time and enhanced the appearance.

- They had competitive pricing since there were local contractors that were trained and understood how to build retaining walls that bid on the projects. The crew size had typically been around 4 workers so it stayed competitive since large or small companies could perform the work.

- Estimated that the GRS-IBS construction was 2-3 weeks faster than traditional bridge construction.

- They used red colored block for embedment behind the rip rap to help indicate if scour issues start to occur.

In conclusion, these were very successful GRS-IBS applications that showcase the future potential for all county governments across the US and Canada. Due to the success of these 4 projects, Hamilton County plans on replacing 2 bridges every year for the forseeable future using this application.

Building GRS-IBS Structures with SRW vs. CMU

Hamilton County upgraded the facing element by using Allan Block for the GRS-IBS structure. The FHWA does not have a standard that required using segmental retaining wall products as the face since the design methodology refers to using CMUs. Obviously, the reinforcing grids are tightly spaced so the connection to the geogrid or the actual pressure exerted on the back of the block is minimal, but there are very good reasons to use SRW units instead of CMUs.

ASTM C1372 outlines the requirements for segmental retaining wall units (SRWs) and provides minimum standards not only for block durability, but also dimensional tolerances. There is no mortar being placed between the blocks when constructing GRS-IBS structures. Therefore, the blocks need to have strict dimensional tolerances so they stack up and install evenly.

For walls and abutments constructed in colder climates designers need to be aware of the freeze/thaw conditions and how it influences block durability. SRW units have been used for retaining wall construction for almost 30 years and as an industry they are pushing for block testing and higher durability standards in cold weather conditions. Producers are aware of these conditions and have SRW units tested accordingly. This testing is not normally done on CMU units.

If you look at the original GRS-IBS designs they will often use a solid CMU or fill hollow CMUs with concrete when they are at or below the water level. The reason for this is that the block may crack if something impacts them. CMU block have a face shell thickness of about 1 in. (25 mm), compared to over 4 in. (100 mm) for an Allan Block unit. Therefore, solid blocks are not required below or at the water line when using Allan Block units. Also using the same block throughout construction minimizes potential errors by the contractor when placing wall units.

Very often a different color CMU block is used for the solid units to indicate if future erosion is taking place. However, this could be accomplished with Allan Block as well since multiple colors are available as seen in this picture from one the Hamilton County projects.

CMUs do not have a built-in shear mechanism like the front lip of the Allan Block units. This front lip not only provides shear strength to each course of block, but helps create wall stability and aids in installation. The front lip acts as a guide for the next course of block so the setback is built into the system and it takes the guess work out of the installation.

GRS-IBS applications provide an economical solution to the countless bridges that need to be replaced. The FHWA indicates that 24% of the bridges across the country are in need of immediate attention. The hope is that more counties will utilize this technology and that designers will recognize the value of using SRW units as the facing element instead of CMUs.

Road and Bridge Planning, Construction, and Rehabilitation

“Some 73% of federal aid for state transportation programs goes to help states plan, build, and make major repairs to their roads and bridges. These programs help assure that the National Highway System, which carries about 85% of the vehicle miles driven nationally each year, continues to efficiently transport goods and people as the economy grows over time.” Federal Highway Administration, “2010 Status of the National’s Highway, Bridge and Transit: Conditions & Performance,” p. 2-12, https://www.fhwa.dot.gov/policy/2010cpr/pdfs/chap2.pdf.

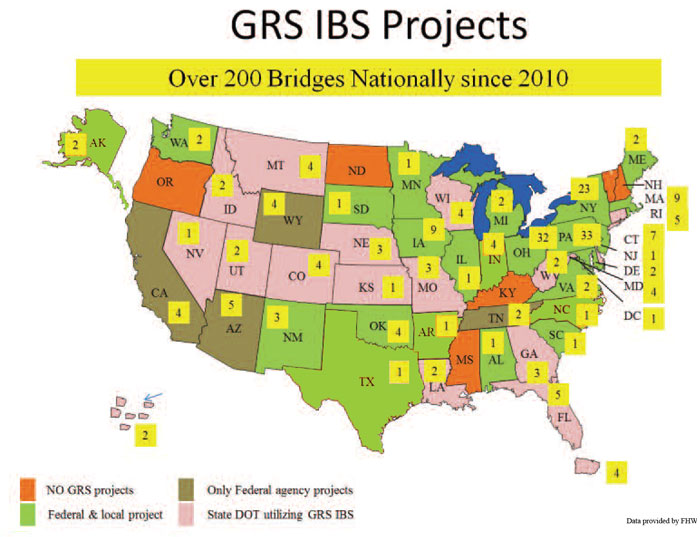

Past GRS-IBS Projects

There have been projects in just about every state in North America since 2010. Make sure you are not missing out on a opportunity where Allan Block can provide an economical solution.

To see if there are projects in your area, start by checking with your local municipalities.

AB Walls Online Training Series - Earn CEU’S

Allan Block has created an online training series for Engineers. This series begins with basic and advanced tutorials on the AB Walls Design Software. Engineers now have the ability to register and sign in to watch individual videos within the training series.

Like all Allan Block training modules, the online training series complies with the IACET requirements and allows AB Corporate to award CEU's. In order to request a credit hour for online training, you must first complete individual assessments upon watching each video.