Technical Newsletter

Issue 12

Sierra Facing Series

Cascade Facing Series

Colonial Facing Series

Cascade Facing Series

Long Anchoring Unit Construction

Sierra Facing Series

Allan Block Shows Off AB Fieldstone®

AB Fieldstone is the next generation Allan Block that is unlike anything else on the market. This new multi-piece system allows you to use lighter weight individual units that easily assemble into a real structural assembly. Also, due to its unique design, it has a number of Green, Natural, and Friendly features.

Green:

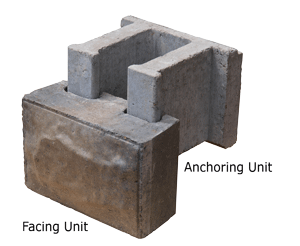

The patented multi-piece system allows the use of recycled materials in each assembly without sacrificing the beautiful appearance of the facing unit. The system consists of anchoring units that easily attach to the facing unit. Since the anchoring units are not visible in a completed wall they can be manufactured with additional recycled material. AB Fieldstone retaining walls can also help projects achieve LEED points in 14 different credits. By using the AB Fieldstone Collection you can build projects that are environmentally friendly applications to help with soil erosion and water management.

Natural:

AB Fieldstone has a variety of appearances that replicate natural stone at a fraction of the cost. Multi sized units allow you to create a natural random appearance. The numerous textures and colors available make AB Fieldstone the “cultured stone” of the segmental retaining wall industry. We currently offer two sculpted stone options, Sierra and Cascade Series, and our brand new flagstone look, the Colonial Series.

Friendly:

Installation procedures are very similar to conventional segmental units but these ergonomically-friendly blocks are easier to lift and stack. Built-in corner pieces speed the assembly of corners with no special blocks or custom cutting required. Additionally, you have the ability to build a substantial gravity wall (with the available 2 ft (0.6 m) anchoring units) without the need for heavy equipment. Taller gravity walls with less excavation and lower labor costs provides designers with more options for their clients.

The Advantages of a Retaining Wall: The AB Fieldstone Collection

Although AB Fieldstone is a new product that offers many unique advantages over previously available SRW products, the engineering and design principles remain the same. Additionally, it has been proven in both the field and lab with all relevant testing completed, including:

AB Fieldstone Collection

- Compression testing

- Absorption testing

- Block-Block Shear testing

- Freeze Thaw Durability Testing

- Block-Grid-Block Shear testing

- Geogrid connection testing

As a direct result of the proven characteristics of the product we have gained following approvals.The AB Fieldstone product meets all requirements of NYSDOT’s Standard Specification “704-07 Segmental Retaining Wall Blocks” and it has been included as such in the relevant subsection of NYSDOT’s Approved List for inclusion/use in NYSDOT’s projects.

- NY DOT Approved

- IAPMO Approved

The numerous advantages AB Fieldstone offers, allows you to provide more options and solutions to your clients. The two piece configuration provides even more flexibility for systems that are designed to move. As these systems are constructed on non-rigid bases, the joint between the face unit and the anchoring unit provides even more flexibility for your projects. From a design standpoint, one of the biggest advantages AB Fieldstone offers is the ability to design and build taller gravity walls than is possible with conventional SRW units. By utilizing the 2 ft (0.6 m) long anchoring units, you can design gravity walls up to 9 ft (2.7 m) tall in optimum conditions (granular, 36° friction angle soils, with a level top and no surcharge). Additionally, because AB Fieldstone consists of multiple, relatively lightweight pieces, a reasonably tall wall can be built without the need for heavy equipment, as is the case with large wet cast blocks. This can provide a substantial cost savings for your project when compared to large blocks or cast in place solutions.

If your project requires an even taller gravity wall, you can use No-Fines Concrete as backfill to provide additional mass. No-Fines Concrete backfill installed to a depth of 35 - 40% of wall height is sufficient for most applications. This is a great solution for taller walls with insufficient space for geogrid reinforcement as was the case for the wall shown here.

Of course AB Fieldstone can be designed as a traditional grid reinforced wall as well. As indicated, we have connection testing and shear testing results with a number of grids and this is all incorporated in AB Walls 10 design software. AB Walls 10 is an industry-leading SRW design software that fully supports all Allan Block products including AB Fieldstone. Not only can you design AB Fieldstone but you can compare different design options by modeling gravity, No-Fines Concrete backfill and grid reinforcement options.

Just as in designing the retaining walls, constructing an AB Fieldstone wall follows the same basic principles as do conventional SRWs. Installation techniques are virtually identical to conventional modular block walls, with the only difference being that facing units and anchoring units are installed as separate pieces. They are ergonomically easier to handle and lighter weight; which allows for faster installation with less worker fatigue.

Another unique feature of the AB Fieldstone Collection is there are no special corner blocks. Outside and inside corners are built-in to typical units. This feature provides a number of benefits including:

- Facing unit heights will always match other units.

- Colors will always match other units

- Outside corners have no “rights” and “lefts” as the facing units can be flipped upside down during installation.

The unique manufacturing method of the AB Fieldstone Collection also provides additional benefits that facilitate easier, faster construction.

- Blocks are manufactured in a way which assures height control is no longer an issue. Shimming is very rare because all facing units are made to exact heights.

- The relatively small footprint of the facing unit is easier to level than typical units.

- Because the levelness of the wall is controlled by the facing units, the wall system is more forgiving in the leveling of anchoring units.

Along with the benefits of a green product and a more natural appearance, Allan Block’s Fieldstone Collection provides numerous advantages that save installers time, energy and money; all while offering more solutions to soil retention and greater flexibility.

Benefits of the Anchoring Unit

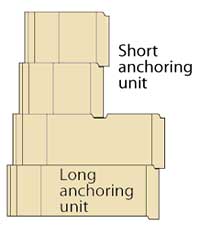

You can build taller gravity retaining walls with the AB Fieldstone Collection utilizing the long anchoring units. However, it is not necessary to install long anchoring units all the way to the top of the wall when there is no surcharge or slope above the wall. Lateral forces are greatest near the base of the wall; but the short anchoring units provide more than enough mass to retain soil for the top two or three courses. This is a great benefit for projects where additional space is needed for plantings or shallow utilities near the top of the wall.