Technical Newsletter

Issue 1

Project Information

Name: High Pointe Commons

Harrisburg, Pennsylvania

Product: AB Classic

Certified Allan Block Contractor:

K & M Dri-Lay Masonry, Inc.

Allan Block Manufacturer:

Nitterhouse Masonry Products, LLC -Chambersburg, Pennsylvania

Successful Projects Start by Using the Right Tools

High Pointe Commons, a large scale commercial project in Harrisburg, PA, has 6 different retaining walls totaling more than 24,000 ft² (2230 m²). With just one of the retaining walls being over 700 ft (213 m) long and a maximum height of 18 ft (5.48 m) tall, the project required a plan, design and build approach that kept all parties informed. K & M Dri-Lay was the wall installer and even with a few weeks of difficult weather conditions that flooded the site, completed the construction in 90 days.

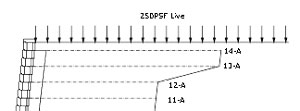

All of the walls have either a slope or paved surface above, requiring special design and construction consideration. Keller Engineering used the AB Walls Design Software to engineer the walls, taking advantage of its design flexibility when modeling surcharges. Here is just one of the design considerations they examined for the project:

When to Lengthen the Top Geogrid Layers

The designer should consider lengthening the top layers of geogrid reinforcement for two reasons:

(1) Wall Stability

When slopes and/or surcharges are present above the retaining wall there are greater forces distributed to the top layers; especially those forces working to pull the geogrid out of the soil. Lengthening the top grids adds an immediate benefit to the pullout of soil calculations and the overall stability of the top of the wall.

(2) Performance Enhancement

The reason to lengthen the top grids with pavement above is to minimize the potential of future cracking, which can shorten the life of the paved surface as well as the life of the retaining wall by allowing water to migrate through the crack into the infill zone. An engineer should consider the reinforced soil mass and retained soil mass as separate structures working independently. Although there is no relative movement between the two zones, a defined construction joint remains. By bridging the construction joint with extended geogrid layers you disrupt any variations between them, such as settlement, and minimize the potential of future cracking of the paved surface and ultimately increasing the life of both the pavement and the retaining wall. For a further discussion on High Pointe Commons and other Allan Block projects see the case studies section of our site.

Going Green with Allan Block Retaining Walls

Allan Block Corporation is an environmentally conscious company that strives to be a leader in the future of "green" building products. Building with more environmentally useful products will increase efficiency and reduce the negative impact we have on the world we live in. As a leader in the industry, Allan Block provides environmental solutions to just about any landscape. Our efforts to provide green construction solutions coincide with the efforts of the U.S. Green Building Council’s LEED® (Leadership in Energy and Environmental Design) Program and other programs of its kind. See a detailed description of how Allan Block products can help your project achieve LEED® Credits.