Print Case Study

Project Information

Name: Community Center Drive

Northglenn, Colorado

Product: AB Ashlar Blend

Size: 116,000 ft2 (1,485 m2)

Local Engineer: Suzanne Wohlgemuth

General Contractor & Wall Builder: HBG Flatirons, Inc. & Slaton Brothers, Inc.

Allan Block Manufacturer:

Basalite - Denver, Colorado

One of the largest patterned retaining walls using the AB Ashlar Blend to-date

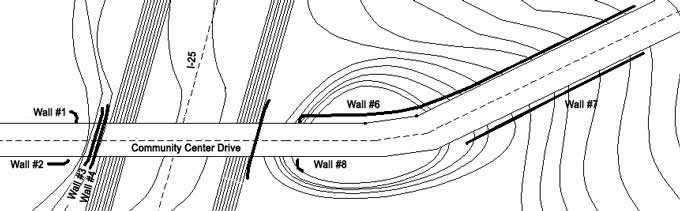

This 8 wall project contains 3 retaining walls that are used as bridge abutments

The bridge abutments and the retaining walls under the overpass were terraced to add more beauty

Retaining walls are specially made to be more vertical than the standard AB Ashlar Blend to conform to CDOT regulations

Allan Block Ashlar Blend Moves in BIG!

Basalite Concrete Products, out of Denver Colorado, has completed the largest square foot Allan Block Ashlar Blend retaining wall project to date. The eight-wall project is located north of Denver along Interstate - 25, a major thoroughfare in the Denver metro area. The 16,000 ft2 (1,485 m2) of retaining wall makes this project a giant AB Ashlar Blend billboard. This project of bridge abutments and terraces is not only the largest AB Ashlar Blend project thus far it's also the first Ashlar pattern that uses a three-degree wall batter.

Plan

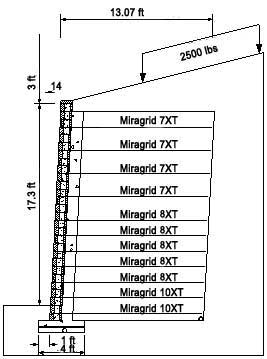

Cross Section

The Community Center Drive project began with one goal; using the Allan Block Ashlar Blend pattern. However, the Colorado Department of Transportation's (CDOT) specifications required the retaining walls installed to have a near vertical batter. In order to install the Ashlar retaining wall and still conform to CDOT's specifications, Basalite needed to reconfigure their block molds from a six-degree system to a three-degree system for this project. HBG Flatirons, Inc., the general contractors for this eight-wall project were able to bring in Slaton Brothers Inc., the largest DOT retaining wall installer in Colorado, to construct the retaining walls. With these two experienced contractors on the job, the project was sure to be a success.

Design

With three retaining walls being used for bridge abutments to support Community Center Drive at its overpass of Interstate 25 and the remaining walls being terraced to run along the side the roadway, this project had a lot of design challenges. The main design challenge faced was finding a way to incorporate the Ashlar Blend while still meeting the CDOT specifications. According to the specifications, the allowable Long Term Design Strength (LTDS) required was 15.7% of the ultimate tensile strength of the grid reinforcement. Under the requirements, the allowable LTDS for Miragrid 5XT dropped significantly from the manufacturers value of 1733 lb/ft (25kN/m) to 675 lb/ft 9.8 kN/m).

This decrease in strength forced the wall design to incorporate longer grid lengths, closer grid spacing, and the addition of stronger grid types, including Miragrid 7XT, 8XT and 10XT. Once these design challenges were met, building these walls began.

Site Plan

Build

Building the walls also brought on challenges. Since the walls were required to have a near vertical batter, the molds had to be altered so that a three-degree block could be made. Altering a block mold and manufacturing new blocks takes up valuable time. To save some time and get the project started, Slaton Brothers began the job by altering the existing stock of six-degree block to the required three degree by hand. While very labor intensive, Slaton Brothers were able to get a jump-start on the project while their three-degree blocks were being manufactured. Once the newly manufactured blocks were ready, the project rolled into high gear. Although this project faced many designing and building challenges, the experience of the contractors and the versatility of Allan Block made it a complete success.