Project Information

Name:

Brenda Cowan Elementary

Lexington, KY

Product: AB Classic

Ashlar Belnd Pattern

Size: 8,700 ft2 (808 m2)

Wall Builder:

Decorative Paving Co.

Loveland, OH

Wall Designer:

Mattingly Engineers

Prospect, KY

Allan Block Manufacturer:

Reading Rock

Cincinnati, OH

New School Includes Stellar New Exterior

Fayette County has been growing and their current elementary schools were bursting at the seams with students, even bringing in portable trailers to serve as classrooms. They needed a new school. The school board, county and local city planning departments worked together to pick the new site along Athens Boonesboro Road. This was a large site that needed your typical clearing and regrading to make it suitable for the new large, one story school. Much planning went into the school interior and exterior design to make the school experience the best it possibly can be for the students and staff. Along with adequate parking for staff and visitors with clear, safe bus lanes for picking up and dropping off students, the planners worked in open recreational spaces behind the school to the west.

Plan:

To facilitate these open recreational grassy areas and playgrounds, the landscape architects planned on regrading the hilly site with two sizable retaining walls. These walls would not only allow for the level playing surfaces but would also act as a separation between the wooded wetlands directly west of the site. The Landscape Architects (LA) first specified the two walls, roughly 8,700 ft2 (808 m2) using large, wet cast concrete block commonly referred to as “Big Block”. The local Allan Block producer, Reading Rock, and their technical representative Michael Baker, set up a meeting with the LA and the site designers to discuss all wall options for the site. Michael, along with local wall designer Mike Mattingly, laid out a clear plan for providing an AB wall that would solve the site grading concerns and provide the desired aesthetic. The most amazing part was that all of this would be accomplished with a much lower installed cost. The original alternative Michael and Mike put together was using the AB Classic block which came in at an astonishing 40% savings over the big block walls proposed. With this eye-opening understanding of Allan Block walls and their cost effectiveness, the LA investigated upscaling the wall to the four block Allan Block Ashlar patterned wall. This type of wall costs a little more in labor and materials but still came in with a 28% overall savings for the project. Armed with this new information the LA and site designers promptly issued an addendum disqualifying the big block specifications in lieu of the AB Ashlar pattern.

Design:

Now that the plan was set and the AB Ashlar Pattern was locked in, Mattingly Engineers started the design process. Both walls have large outside curves and are roughly 15ft (4.6 m) for a maximum height that totaled nearly 800 ft (244 m) long. When asked if there was anything special about this wall, the very experienced Mike Mattingly said “no, they were very straight forward.” Using the Allan Block design software, AB Walls, makes the design process easy. These walls are partial cut-and-fill walls due to the regrading of the site. Mike used Stratagrid 200 at a 2-course block spacing which is the National Concrete Masonry Association’s (NCMA) best practices suggestion that builds a very solid reinforced soil mass.

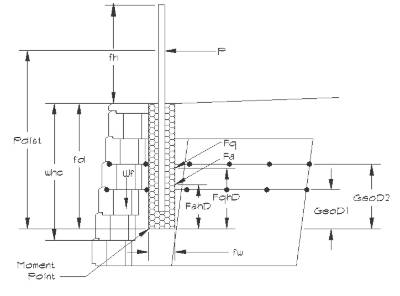

One item to note, is that Mike said he decided to use the tried and true construction tube method of installing the footing for the fences installed above the walls. While the Sleeve-IT system from Stratagrid is becoming very common and is a great product, due to the height of the fences and the proposed wind load, they decided on the construction tube method. This way they could push the footing deeper behind the wall to utilize more of the wall facing and geogrid layers to resist the overturning forces.

Prior to the introduction of Sleeve-IT, designers would install a post footing behind the wall typically in a construction tube, or sometimes by simply driving the post down through the compacted soils and through the geogrid layers. The free body diagram for this uses the bottom of the post as the rotational point and the wind or pedestrian loads push the fence up against the back of the block. The resistance side of the equation is the weight and setback of the facing units and the residual or excess capacity in each layer of geogrid that intersects the post footing. The distance up to each grid layer from the bottom of the post becomes the resisting moment arm for the design check. The basic engineering behind using the simple construction tube is that for every geogrid layer the post footing goes through, the grid layer will help hold the fence post in place and resist the overturning force coming from wind or pedestrians. Using this method, the designer is free to install the post as deep as is required for the fence/railing application and this method can also be used for light duty vehicle guardrails as well.

Build:

Once the design was complete a competitive bid was released with the added criteria that the bidding contractors would be Allan Block Certified Installers. These are contractors that have successfully completed the Allan Block Certification Course and have completed a number of projects following the course. By adding this criterion to the bid package, Fayette County was assured to get a quality, experienced contractor to build this important project. And they did. Bryant Snider and his crew from Decorative Paving Co. out of Loveland, OH easily qualified for this project. Decorative Paving are Allan Block Master Wall certified installers that builds many Allan Block projects each calendar year. Like Mattingly, when asked about this project and if there was anything that stood out as difficult or special, Bryant said that “all projects have a certain amount of complexity to them, but with a good set of plans, a quality design and quality staff, this project like all their projects, ran smoothly."

They built the wall as designed, with Stratagrid SG200 with 2-course maximum block spacing and the grid lengths were equal to at least 60% of the wall height. For the top of each wall, they coordinated with the fence installer the location of the post footings and installed a 4 ft (1.2 m) long by 12 in. (300 mm) diameter construction tube at each location. After making sure each was installed plumb and level, they installed temporary lateral bracing to each to make sure they stayed in place while continuing to build the remaining courses of block, backfill and grid placement. They followed the typical geogrid installation instructions of slicing the transverse member and splaying the strong members around each construction tube. They backfilled and compacted the wall rock and infill soil as typical around the tubes, while taking care to not let the tube get filled with material along the way.

Once the wall was complete, the fence installer cut off the excess tube to be just below finished grade and installed the fence posts. Once the posts were installed, they were then able to complete the fence panel installation and call the project done.

Like both Mike and Bryant said, this was a pretty uneventful project; but we at Allan Block know it’s due to their proper planning and communication at all levels. And let’s not forget that this project would have never been if Michael and Mike had not taken that first step to educate the LA and site designers on the tremendous value Allan Block can bring to any site, especially those being specified as Big Block.

Special Interest:

During the planning of the school, it was unanimously voted on by the Fayette County Board of Education to name the school after the first African American Female Firefighter to serve their community. Brenda Cowan died in the line of duty in February of 2004 while responding to a domestic disturbance. On opening day, the ribbon was cut by local firefighters and other first responders, city and county officials and members of Brenda’s family.